| Availability: | |

|---|---|

| Quantity: | |

NJY-600C

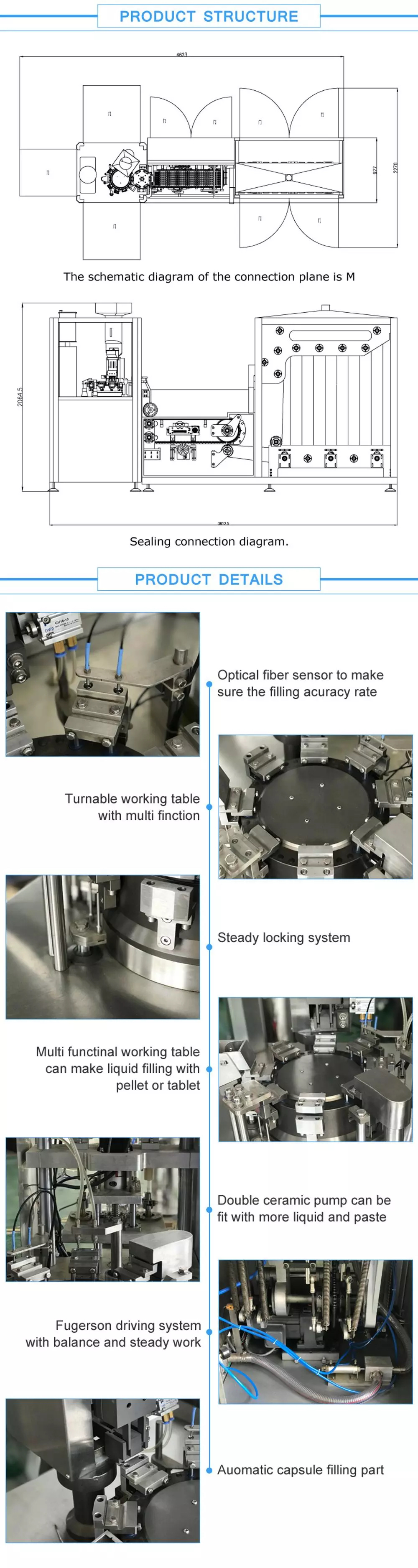

This high-performance oil liquid capsule filling machine specializes in filling oily liquids, solutions, suspensions, and pastes into capsules (sizes 00-4#) with exceptional accuracy. Equipped with advanced technologies such as optical fiber sensors and a Fugerson driving system, the NJY-600C ensures stable operation, consistent filling precision (±2%), and reliable production efficiency. Its robust design, multi-functional working table, and compliance with international standards (ISO, CE) make it a top choice for manufacturers seeking scalable, high-quality filling solutions. Whether for mass-producing fish oil capsules, liquid drug formulations, or cosmetic essential oil capsules, the NJY-600C delivers unmatched versatility and performance, driving productivity and product excellence.

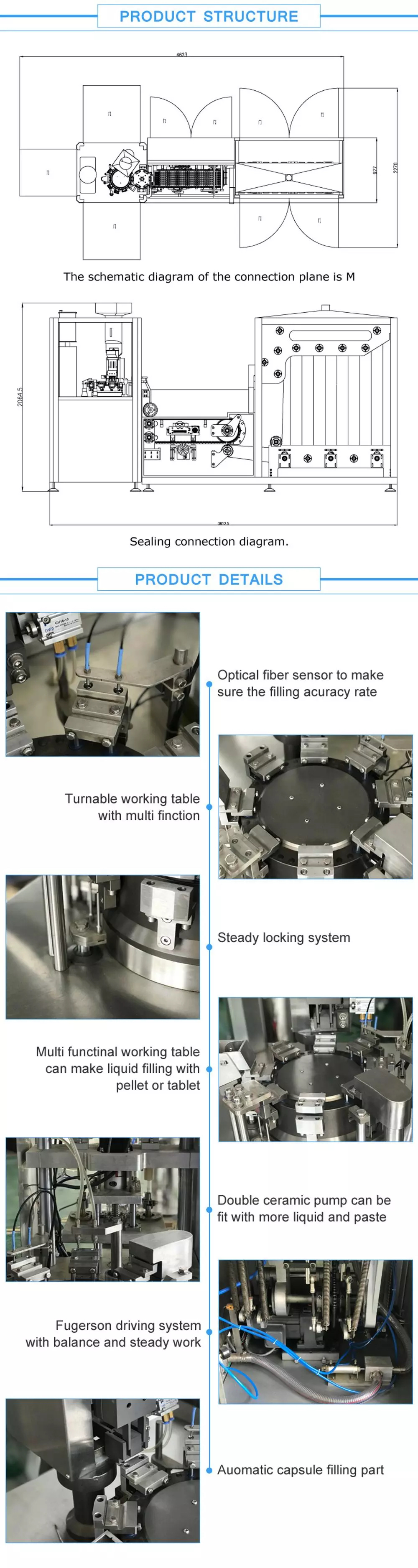

The NJY-600C boasts liquid loading accuracy of ±2%, guaranteed by integrated optical fiber sensor technology that detects and adjusts filling volumes in real time. This precision minimizes product waste, ensures dosage consistency, and meets strict regulatory requirements for pharmaceutical and supplement products.

Designed to handle a wide range of materials—including oily liquids, solutions, suspensions, and pastes—this filling machine eliminates the need for multiple specialized devices. It adapts to varying viscosities and consistencies, reducing production costs and increasing workflow flexibility for diverse product lines.

With compatibility for capsule sizes 00-4#, the NJY-600C caters to diverse product needs—from large health supplement capsules to small pharmaceutical dosages. This versatility makes it ideal for manufacturers with expanding or varied product portfolios.

The integrated Fugerson driving system ensures smooth, vibration-free operation, reducing machine wear and extending service life. Its balanced design maintains consistent performance even during long production runs, minimizing downtime.

The machine’s rotatable working table supports liquid filling, as well as filling with pellets or tablets. This multi-functional design allows manufacturers to expand product offerings (e.g., combination capsules) without investing in additional equipment, enhancing production versatility.

Equipped with double ceramic pumps, the NJY-600C handles various liquid viscosities and paste consistencies with ease. Ceramic pumps are corrosion-resistant, durable, and easy to clean, ensuring hygienic operation and low maintenance requirements.

Weighing 750KG, the machine features a heavy-duty frame and high-quality components that withstand industrial use. Its robust build ensures long-term reliability, supports continuous production, and maximizes return on investment for manufacturers.

In pharmaceutical manufacturing, the NJY-600C fills liquid drug formulations (e.g., antibiotic solutions, herbal extracts) into capsules, complying with GMP standards to ensure product safety, efficacy, and regulatory compliance.

For health supplement producers, the machine is ideal for filling fish oil capsules, vitamin E capsules, and other oil-based supplements. It maintains product freshness, delivers precise dosages, and supports large-scale production to meet market demand.

In the cosmetic industry, the machine fills essential oils (e.g., lavender oil, tea tree oil) into capsules, catering to the growing demand for convenient, mess-free cosmetic products. It ensures clean, precise filling to preserve oil potency.

The NJY-600C fills liquid food supplements (e.g., collagen suspensions, probiotic liquids) into capsules, meeting food safety regulations and enhancing product portability for consumers.

For the chemical industry, the machine handles small-batch filling of specialty capsules (e.g., corrosion-inhibiting liquids, industrial additives), providing precise, safe packaging solutions for niche applications.

Parameter | Details |

Model | NJY-600C |

The production efficiency | 300 Capsules/minute |

Fill in the material | An oily liquid, solution, suspension, or paste |

Die number | 6 |

Fillable capsule | 00-4# |

The power supply | 380V/50Hz |

The total power | 5KW |

The switchboard weight | 750KG |

Overall dimensions | 860×960×1800mm |

Liquid loading accuracy | ±2% |

The machine is designed to fill oily liquids, solutions, suspensions, and pastes—perfect for pharmaceutical formulations, health supplements, and cosmetic products.

The NJY-600C works with capsule sizes 00-4#, covering most common dosage forms for pharmaceuticals, supplements, and cosmetics.

The machine can fill up to 300 capsules per minute, making it suitable for medium to large-scale production lines.

It operates on a 380V/50Hz power supply with a total power of 5KW, ensuring stable performance for industrial use.

The optical fiber sensor detects filling volumes in real time, adjusting the pump output to maintain a ±2% accuracy rate, minimizing dosage variations and product waste.

We offer a 12-month warranty from the date the machine arrives at your facility, covering manufacturing defects and component failures.

This high-performance oil liquid capsule filling machine specializes in filling oily liquids, solutions, suspensions, and pastes into capsules (sizes 00-4#) with exceptional accuracy. Equipped with advanced technologies such as optical fiber sensors and a Fugerson driving system, the NJY-600C ensures stable operation, consistent filling precision (±2%), and reliable production efficiency. Its robust design, multi-functional working table, and compliance with international standards (ISO, CE) make it a top choice for manufacturers seeking scalable, high-quality filling solutions. Whether for mass-producing fish oil capsules, liquid drug formulations, or cosmetic essential oil capsules, the NJY-600C delivers unmatched versatility and performance, driving productivity and product excellence.

The NJY-600C boasts liquid loading accuracy of ±2%, guaranteed by integrated optical fiber sensor technology that detects and adjusts filling volumes in real time. This precision minimizes product waste, ensures dosage consistency, and meets strict regulatory requirements for pharmaceutical and supplement products.

Designed to handle a wide range of materials—including oily liquids, solutions, suspensions, and pastes—this filling machine eliminates the need for multiple specialized devices. It adapts to varying viscosities and consistencies, reducing production costs and increasing workflow flexibility for diverse product lines.

With compatibility for capsule sizes 00-4#, the NJY-600C caters to diverse product needs—from large health supplement capsules to small pharmaceutical dosages. This versatility makes it ideal for manufacturers with expanding or varied product portfolios.

The integrated Fugerson driving system ensures smooth, vibration-free operation, reducing machine wear and extending service life. Its balanced design maintains consistent performance even during long production runs, minimizing downtime.

The machine’s rotatable working table supports liquid filling, as well as filling with pellets or tablets. This multi-functional design allows manufacturers to expand product offerings (e.g., combination capsules) without investing in additional equipment, enhancing production versatility.

Equipped with double ceramic pumps, the NJY-600C handles various liquid viscosities and paste consistencies with ease. Ceramic pumps are corrosion-resistant, durable, and easy to clean, ensuring hygienic operation and low maintenance requirements.

Weighing 750KG, the machine features a heavy-duty frame and high-quality components that withstand industrial use. Its robust build ensures long-term reliability, supports continuous production, and maximizes return on investment for manufacturers.

In pharmaceutical manufacturing, the NJY-600C fills liquid drug formulations (e.g., antibiotic solutions, herbal extracts) into capsules, complying with GMP standards to ensure product safety, efficacy, and regulatory compliance.

For health supplement producers, the machine is ideal for filling fish oil capsules, vitamin E capsules, and other oil-based supplements. It maintains product freshness, delivers precise dosages, and supports large-scale production to meet market demand.

In the cosmetic industry, the machine fills essential oils (e.g., lavender oil, tea tree oil) into capsules, catering to the growing demand for convenient, mess-free cosmetic products. It ensures clean, precise filling to preserve oil potency.

The NJY-600C fills liquid food supplements (e.g., collagen suspensions, probiotic liquids) into capsules, meeting food safety regulations and enhancing product portability for consumers.

For the chemical industry, the machine handles small-batch filling of specialty capsules (e.g., corrosion-inhibiting liquids, industrial additives), providing precise, safe packaging solutions for niche applications.

Parameter | Details |

Model | NJY-600C |

The production efficiency | 300 Capsules/minute |

Fill in the material | An oily liquid, solution, suspension, or paste |

Die number | 6 |

Fillable capsule | 00-4# |

The power supply | 380V/50Hz |

The total power | 5KW |

The switchboard weight | 750KG |

Overall dimensions | 860×960×1800mm |

Liquid loading accuracy | ±2% |

The machine is designed to fill oily liquids, solutions, suspensions, and pastes—perfect for pharmaceutical formulations, health supplements, and cosmetic products.

The NJY-600C works with capsule sizes 00-4#, covering most common dosage forms for pharmaceuticals, supplements, and cosmetics.

The machine can fill up to 300 capsules per minute, making it suitable for medium to large-scale production lines.

It operates on a 380V/50Hz power supply with a total power of 5KW, ensuring stable performance for industrial use.

The optical fiber sensor detects filling volumes in real time, adjusting the pump output to maintain a ±2% accuracy rate, minimizing dosage variations and product waste.

We offer a 12-month warranty from the date the machine arrives at your facility, covering manufacturing defects and component failures.